PRODUCTS

How is Hydradrive constructed?

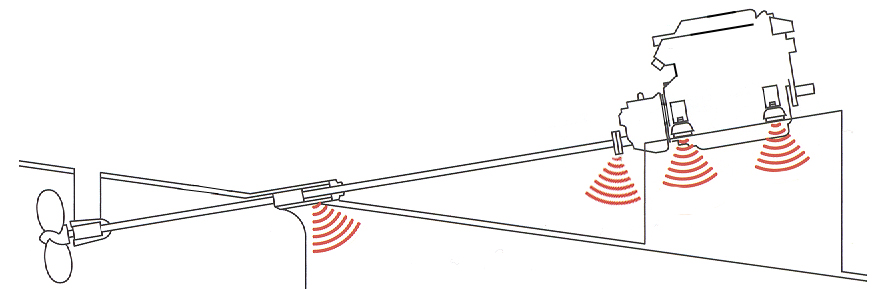

The idea is based on a simple principle. The engine mounts can be very soft and thereby isolate well against noise and vibrations. For optimal result the thrust forces from the propeller must be transferred directly to the hull via the thrust bearing, independent of the gearbox and engine. Normally the propeller thrust is transferred to the hull via the engine mounts. With Hydradrive the thrust forces goes directly to the hull via the thrust bearing on the propeller shaft. The rotation movement is transferred thru a CV shaft (Constant Velocity shaft).

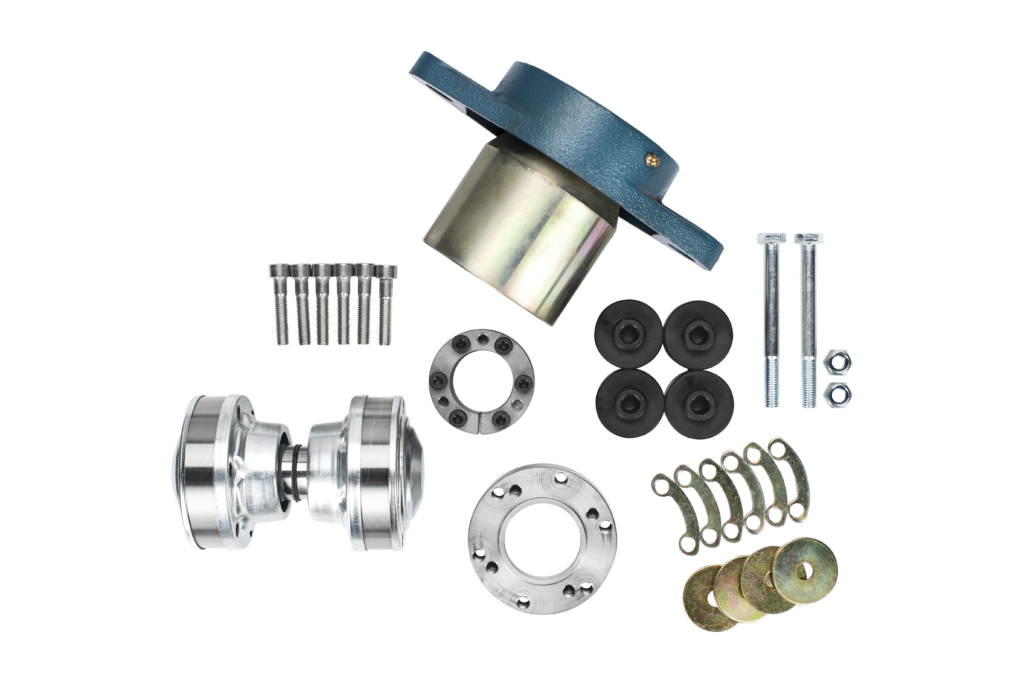

A complete Hydradrive installation includes CV shaft, thrust bearing, adapter between gearbox and CV shaft

and engine mounts.

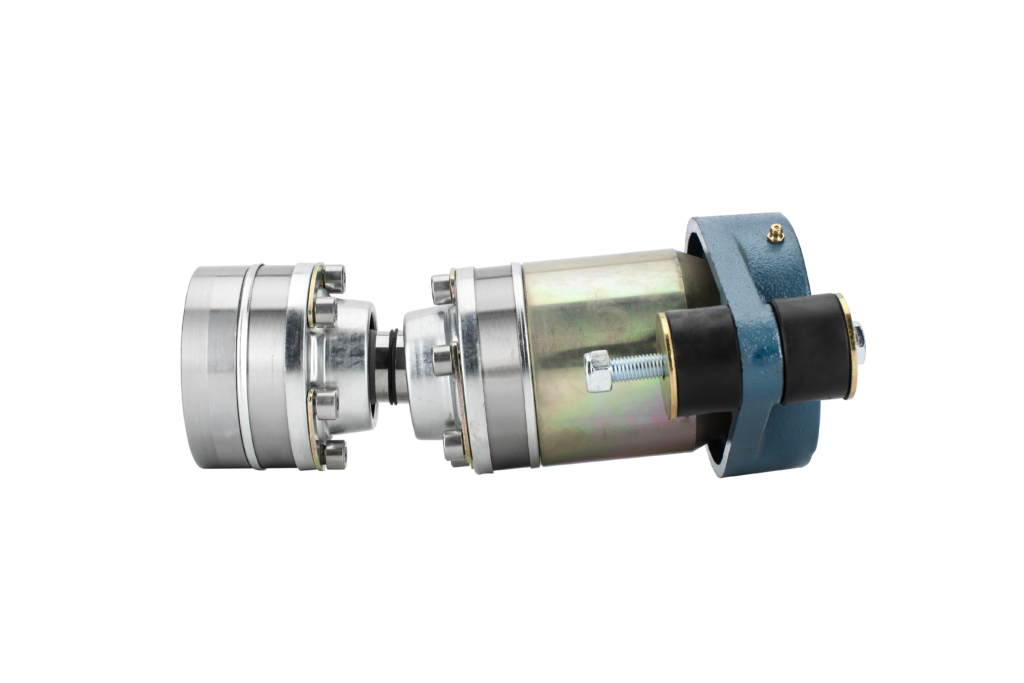

The CV shaft is the main component in the installation and functions like the drive shaft on a car. In a boat this means that the torsional power is transferred via balls, and the shaft absorbs axial movements in the system. This leads to practically no resistance in any direction when the boat moves through the waves. The result is strongly reduced noise, and vibration levels in the boat.

For work boats, with high running hours and higher workloads than pleasure crafts, we have chosen to deliver the system with normal cardan shafts instead of CV shafts. The reason for this is two important facts: The life expectancy is much longer and the dimensions are smaller. But for smaller vessels, however, with moderate power (less than 500 BHP) we recommend CV shafts. Smaller dimensions are of importance since normally there is limited space for the joints at the gearbox.

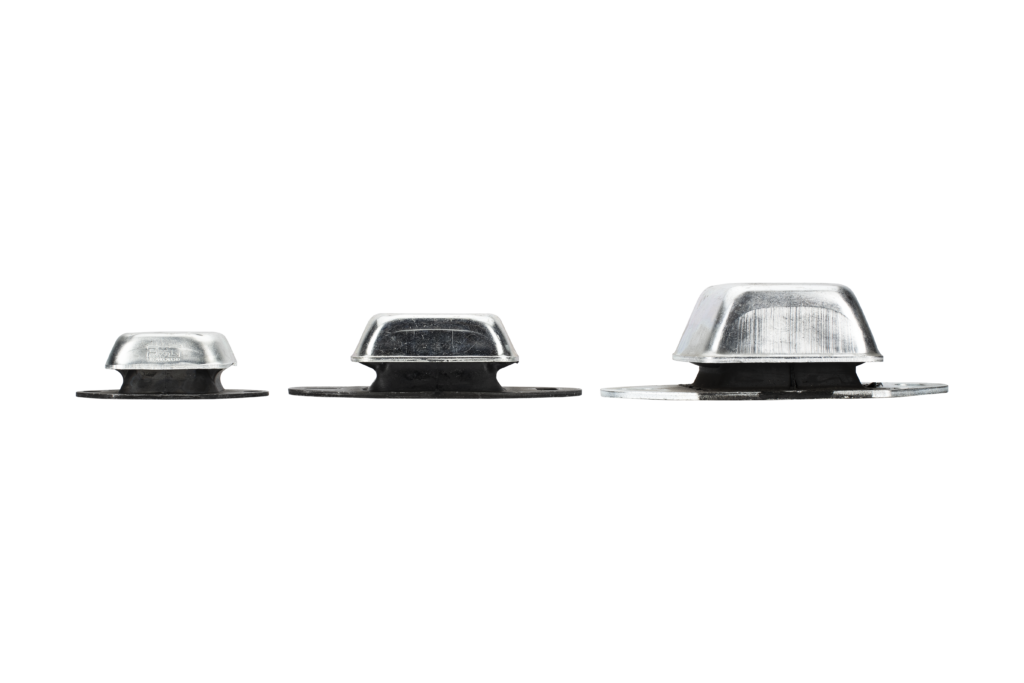

The Thrust Bearing

The thrust bearing is mounted directly in the hull. All sizes up to HD 130 (approx. 280 Bhp) are supplied with spherical bearings that absorb small angular displacements in the installations. All our thrust bearings for CV shafts have clamping units built in. This saves space. For work boats with power over 500 hp we use ordinary flanges.

Adaptors for gearbox mounts

All CV shafts require an adaptor for connection to the gearbox. We have a large variety of flanges that enables us to connect our CV shafts to all well-known gearboxes. Bolts and nuts are supplied with each flange.

Engine mounts

Engine mounts might be the most difficult part of the installation. We recommend using the original mounts if possible to begin with. For those who would like new mounts you can contact our customer service, or contact closest dealer. We supply engine mounts that are adapted to our system. They are chosen due to their stiffness of the rubber. We supply premium quality engine mounts with a built in safety device, this enables you to a certain degree to operate the vessel even if the mounts should break.

The CV-Shaft

Hydadrive parts

A system giving an outstanding technology that brings

the vibration and noise level to a minimum. It simplifies

the installation considerably. We recommend especially the

system for people who are going to re power with another type of engine with other brackets etc. A professional

Company saves a lot of time if installing new engines, a private handyman would save a lot more. Alignment

can be done by visual estimate.

What is the reason for noise and vibrations?

A traditional installation without Hydradrive brings high levels of vibration to the hull, even when perfectly aligned.

The propeller is pushing on the engine mounts. The engine is moving forwards, and the tension between the propellershaft and the transmission increases. The engine has then a tendency to bend upwards. This is the case particularly if the transmission has a dropdown. The noise and the vibration from the propeller itself will be transmitted to the hull, and will often be an extra disturbing noise.

Hydradrive means softer engine mounts.

If using extra soft engine mounts, the result of isolation from the source of noise will be considerably improved.

The thrust bearing unit is also mounted with rubber pads. It is supposed to take the thrust forces from the propeller. The CV – shaft is transmitting the torque. The unique construction of the CV – shaft isolates the engine from the

propellershaft. The flexibility in the cv-joints is a fantastic solution. It´s such a unique solution for use in boats, that

one could think they are invented for this purpose alone! (The construction was meant for use in cars, and done

by a Ford engineer with the name Rzeppa around 1925)

Simpler Installation

Both the CV – joints can take up to 8°. This simplifies the installation dramatically. The alignment can be done by

visual estimate.

Torsional Vibration.

In traditional installations with a gearbox ( Transmission ), there will normally be a rubber based torsional damper

between the gearbox and the engine. In systems without transmission, a torsional damper can be done in two different ways. As a resilient tubing on longer shafts, or as damper directly on the flywheel. We please ask you to contact

Customer service.

Dimensioning of Hydradrive

To decide a correct dimension is dependant of many factors influencing each other. To feel safe with your Hydradrive, we recommend to ask Customer service. Some of the factors can still be assumed. Please remember that all given information for performance and angles are approximate. Next page has tables on many of the important numbers for selection of size. If the numbers are close to next size, we please ask you to oversize.